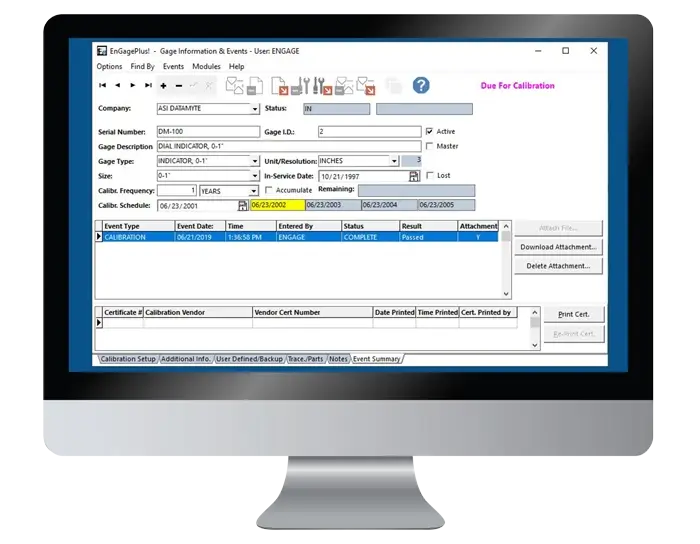

Intuitive Gauge Management, all in one place.

Maintain all gauge information electronically, including gauge history and calibration records. Intuitive functionality includes colorful graphics, menus, and a floating tool bar for instant access to major functions.

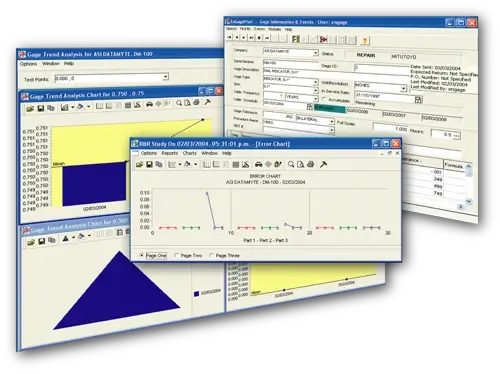

EnGagePlus! has built‐in capability to perform a variety of gauge studies, including Gauge R&R, bias, stability, and linearity. The user has the option of performing either standard or ANOVA R&R studies. EnGagePlus! automatically maintains all study events as part of each gauge history, and is compliant with the MSA 3rd Edition Gauge R&R and ANOVA analyses.

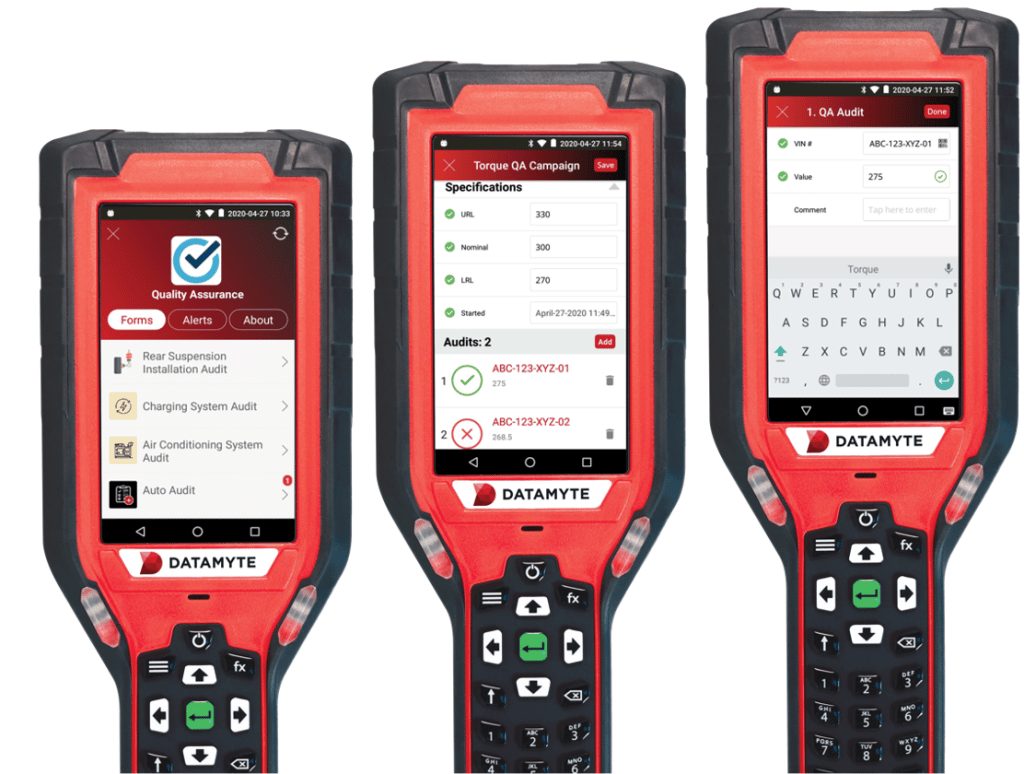

Now you have a choice: parts or processes.

Quick retrieval of gauge information, inventory location, and calibration certificates

Schedule gauge certification notifications to ensure compliance

Reduce errors from manual documentation and audit issues

Single source for all gauge history with an intuitive quick search