What are the Sources of Error in Measurement

Error in measurement can result even with the best of equipment and measuring techniques. A measurement error is the difference between the measured value of a magnitude and the true value. This difference from the true value can be a problem of accuracy or precision.

Several sources of error exist in most instruments — nonlinearity, hysteresis (e.g., gear backlash), and sensitivity to environmental factors such as temperature, magnetic fields, or electrical fields. Instrument error is often magnified by the fixturing required in the measuring process. Poor electrical connection, improper fastening of mechanical linkages, and loose clamps are examples of fixturing problems. Temperature-induced error, in addition to its effects on measuring instruments, affects the specimen being measured. As temperature changes, the length (L) of a specimen changes as follows:

∆ L = (L) (∝) (∆T

where: L = original length of the specimen (7.5.1)

∝ = thermal expansion coefficient

∆T = temperature variation

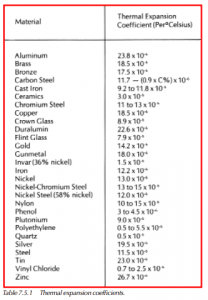

Table 7.5.1 gives the thermal expansion coefficients for several industrial materials.

Deformation

Deformation is the second largest source of error following temperature. Deformation can be caused by the following:

- Force exerted on a specimen by the measuring instrument.

- Placement of the specimen supports.

- Placement of the instrument supports.

A compression force (within the elastic limit) will cause deformation. The deformation (DL) can be calculated as follows by Hook’s law:

where: F = measuring force, Kgf (7.5.2)

L = length of test piece in mm

E = Young’s modulus, Kgf/mm2

A= cross-sectional area in mm2

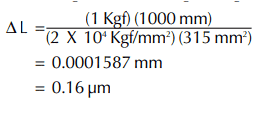

An example using Hook’s law is as follows: a gauge block (A = 9mm x 35mm = 315mm2 and L = 1000mm) is measured with a measuring force of F = 1kg. Young’s Modulus for steel is E = 2 x 104 kg/mm2 . The deformation would be as follows:

Operator Error

There are several sources of operator error that will cause variation in the data that is recorded. An operator of a measuring system can get different results even when measuring the same product and using the same measuring system. This is due to the fact that even with the same operator there will be slight differences in measuring techniques from one measurement to the next. When two operators are measuring the same product with the same measuring instrument, the differences can be even greater due to differences in measuring techniques. Depending on the measuring technique, variation in data can be more dispersed or show up as a systematic error.

Variations in recorded measurements can also be evident if different test procedures are used to measure the same product. Different test procedures can introduce variation in measurement techniques if they are not carefully designed. Errors in data often occur when the operator takes a reading from the instrument and then enters it on a form or similar media. These errors can consist of transposing numbers, recording incorrect numbers, or writing illegible numbers, causing transcription errors to occur when the data is later analyzed.