What is Chicken Processing Business

Chicken Processor Increases Food Safety, Standardizes Quality, and Increases Profits with DataMyte 3055 Data Collector and Quantum SPC/QA Software

A chicken processor was in an ultra-competitive market and committed to applying the latest technologies to assure customers the highest quality product. That meant finding a way to maintain constant oven temperatures while cooking millions of pounds of chicken a year for the “ready-to-eat” market.

To meet safety-conscious customers’ requirements, the company had a long-established Hazard Analysis and Critical Control Point Program (HACCP), evolved from the nation’s space programs, in place. The HACCP standard was voluntarily applied to monitor and control foreign object hazards, chemical hazards, and microbiological hazards in the food. Each of the critical HACCP control points was considered important. However, special attention was given to the control of microbes.

In processing, the company cooked chicken until the internal temperature reached 160º F. To achieve this, a 4-ounce piece of chicken remained in an industrial oven for approximately 5 minutes and was heated to temperatures of approximately 320º F. To measure and assure proper cooking temperature, employees regularly probed the thickest part of the cooked chicken with an electronic thermometer.

Problem

In the past, data from as many as 300 points per hour were gathered during a chicken production run and were analyzed in the QA lab. To be certain the 160º F target was met, ovens were sometimes heated to 400º F and the internal temperature of chicken was raised to 180º F, resulting in overcooking. The result was reduced moisture and lower subsequent yield on a run, as well as a negative impact on product quality.

Because the company was committed to continuous quality improvement, some other method of quality control had to be found. The processor needed an instantaneous measurement of the standard deviation for the run

Solution

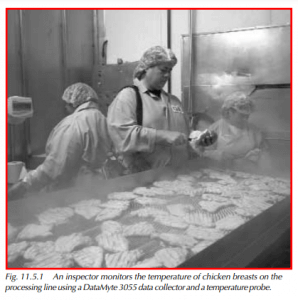

The company’s solution was found in DataMyte 3055 data collectors and Quantum SPC/QA software. The chicken processor installed DataMyte data collectors on each of its processing lines to gain instantaneous measurements of standard deviation. Employees used electronic thermometers to probe cooked chicken, and the data was compiled by the data collectors and displayed in updated X-bar & R charts. Further analysis was conducted using Quantum SPC/QA software.

The DataMyte collectors allowed operators to monitor the process in real time, so they could make necessary adjustments in the process and reduce the standard deviation. The result was a reduction in variables around the target temperature to as close to zero as possible.

With measurable success in its cooking process, the chicken processor applied DataMyte data collection technology to monitor its breading pick-up controls. By more closely controlling the amount of breading, or flavors, applied to the chicken, the company was able to maintain its desired quality levels more economically.

Next the company applied DataMyte technology to portion control, a critical issue with food-service customers. The chicken processor used DataMyte data collectors to measure and control portions by weight and dimensional attributes, so their customers could be assured of satisfying consumers and maximizing their own profits. The company also applied the data collectors throughout its “fresh” market to monitor and maintain consistent weight and dimensional attributes.

The chicken processor’s data collector and software installation resulted in better process control, as well as higher product quality and increased customer service. In a highly competitive market, its customers demanded a supplier who could meet specifications. The DataMyte 3055 Data Collector and Quantum SPC/QA Software helped the processor apply the latest technology to ensure high-quality products and high profit ratios.