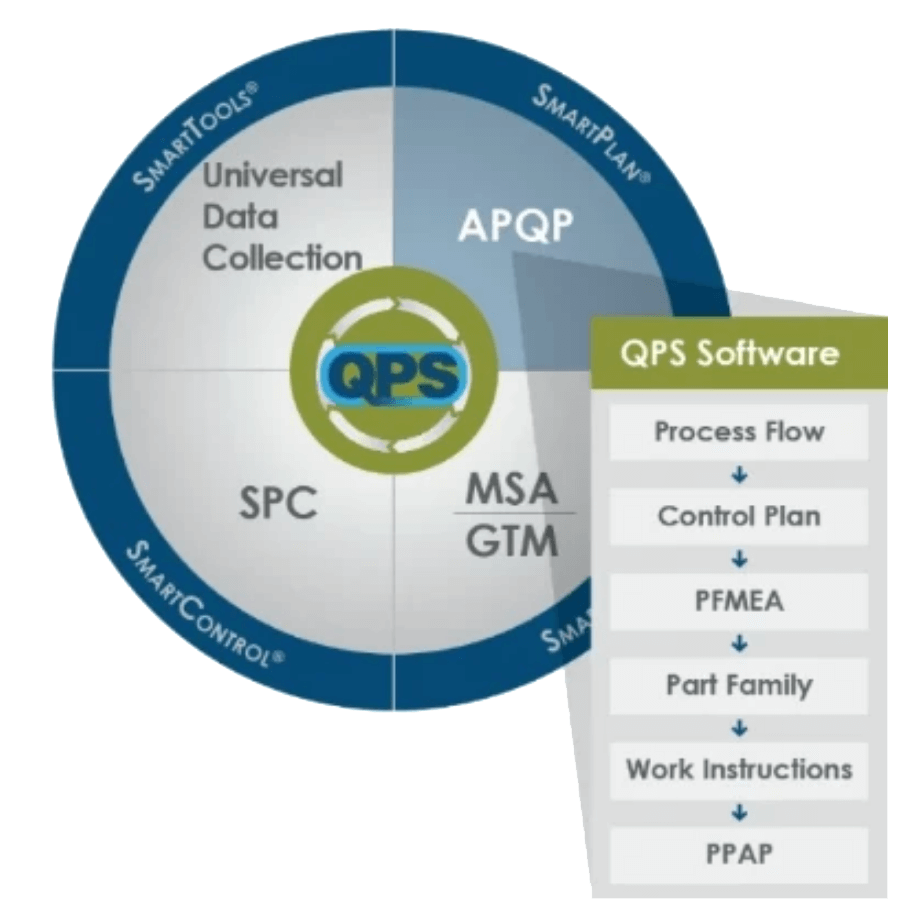

A single, integrated FMEA software tool for planning, documenting and monitoring core quality requirements.

Automate Advanced Product Quality Planning for risk mitigation, increased product reliability and process efficiencies.

Measurements, production specs, and inspections stay up to date to control production parts and processes.

Cascading edits reduce errors and make the PFMEA data compilation simple and always up to date.

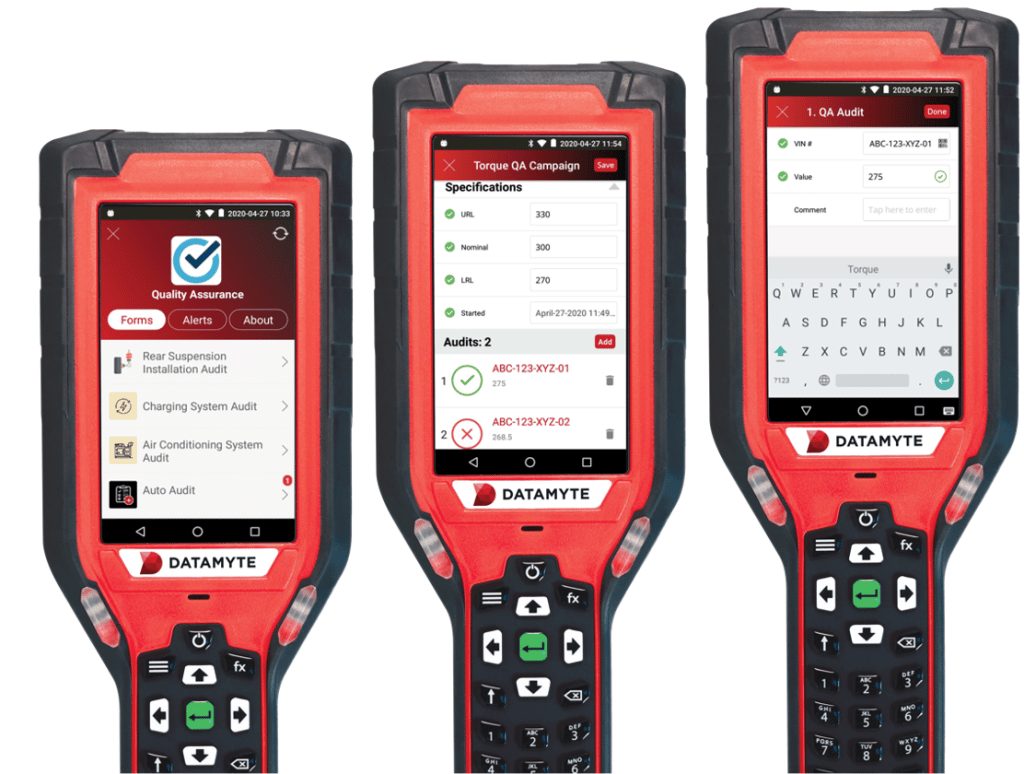

Eliminate paper processes to save time, reduce rework costs and training needs, and increase productivity.

For manufacturers worldwide, FMEA has become synonymous with continuous improvement programs. Process Flows, FMEA, control plan and SPC have a strong inter-relationship. The FMEA process ensures that products, processes or detection techniques are constantly improved.

Continuous feedback is provided from SPC results on the shop floor to engineers responsible for the FMEA process. Quality Planning Studio FMEA software stores all data within the QPS database, ensuring traceability and integrity of your Process Flow/FMEA/Control Plan information across your plants. QPS can also communicate with our SPC software (DataMetrics), allowing you to reduce redundancy and perform characteristic capability monitoring from the Control Plan.

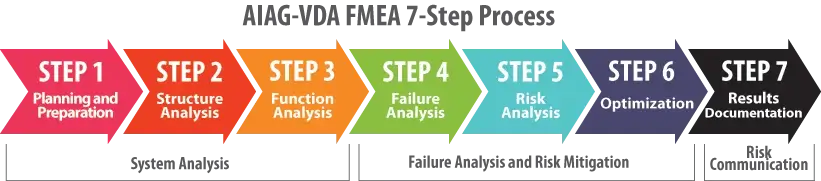

QPS (version 8.4 and later) supports the Process FMEA functionality of both the AIAG 4th Edition and AIAG/VDA 1st Edition publications.

Added Process Step function

Effects of Failure Mode

Severity Values

Causes of Failure

Controls for Prevention of the Cause

Controls for Detection of the Cause or Failure

Occurrence and Detection values

Process Improvement

New Recommended Actions with prevention and detection emphasis

Status Field

Target and Effective dates

Action Prioritization

Risk Communication

Action Priority option for Risk Analysis