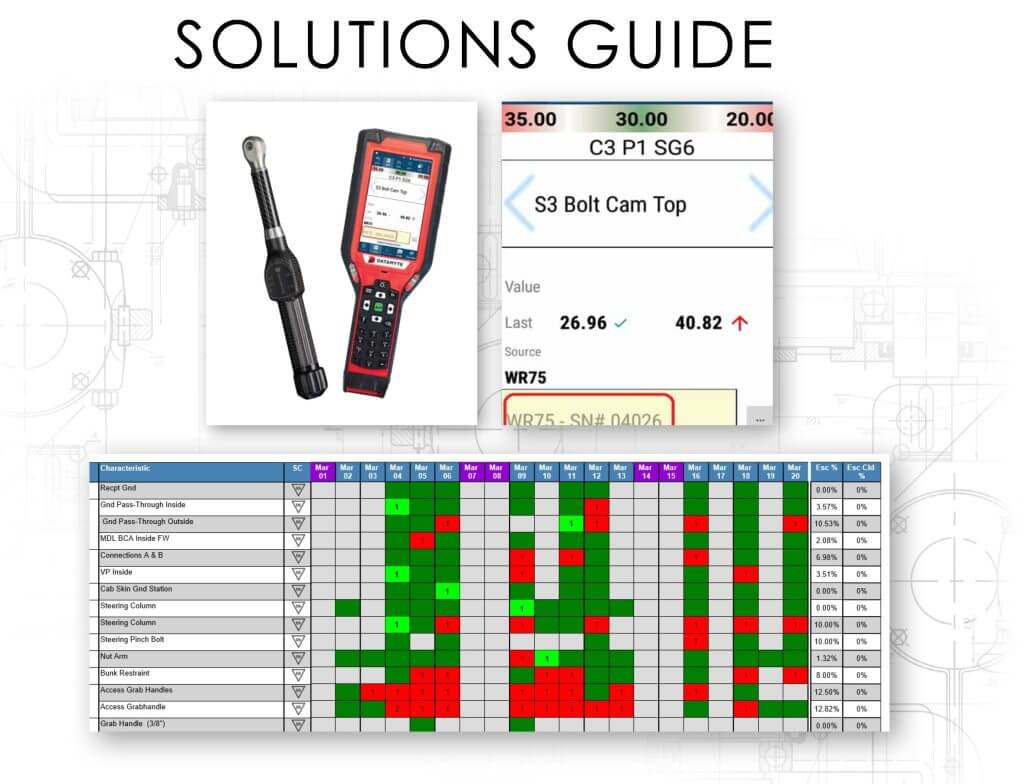

Download our comprehensive Solutions Guide to walk you through DATAMYTE’s approach to managing Residual Torque.

You may have Digital DSL or Analog LSU models of DataMyte Torque Wrenches in your inventory. Now is your chance to get your money back and not have to deal with replacing worn or damaged cables by going wireless.

Take advantage of BUYBACK discounts when you return your older model wrenches.

Move to the Wireless technology to increase your productivity by:

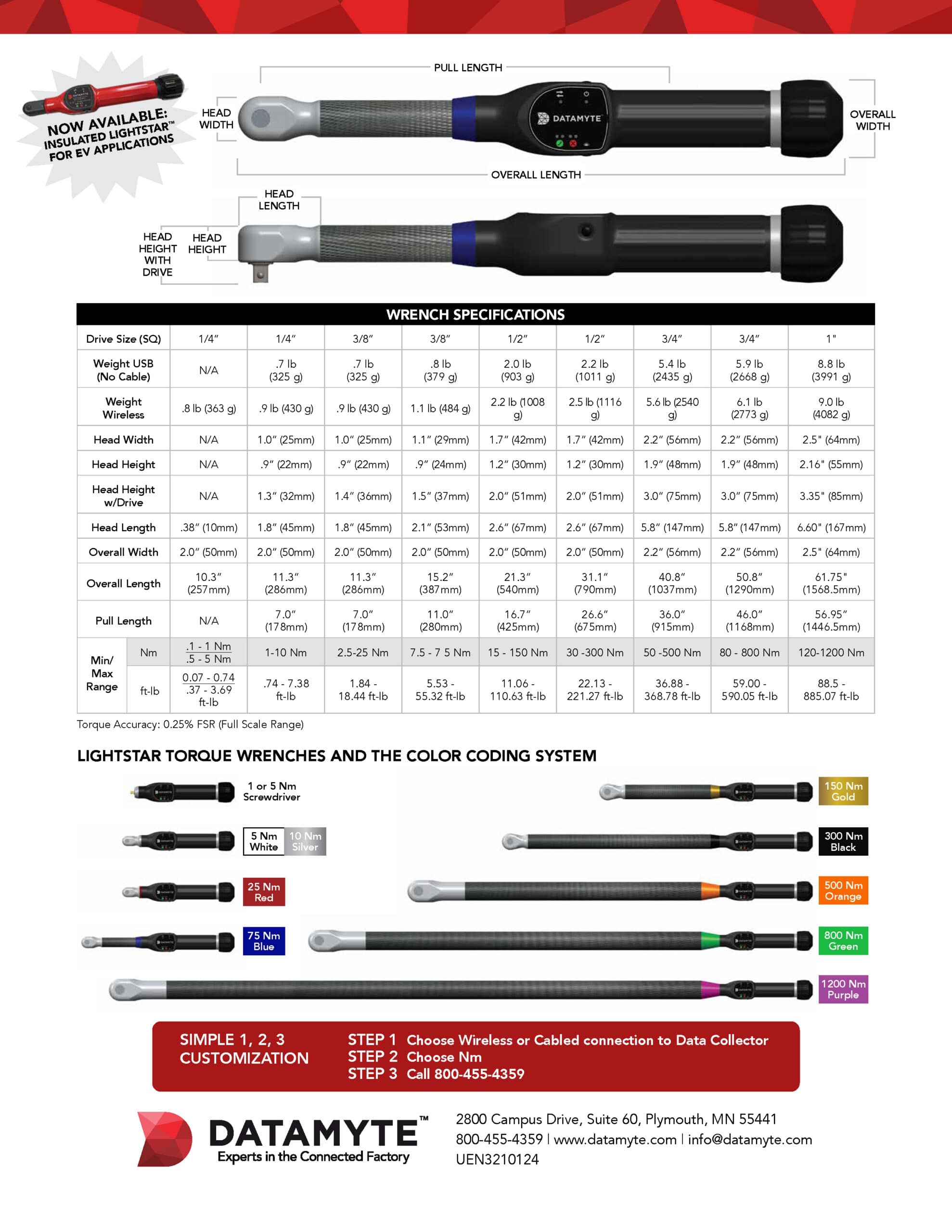

When quality matters you turn to the industry precision wrench expert that aligns the latest technology with your quality goals to drive profitability to your bottom line. When it’s your job to ensure that safety-critical joints are correct, trust only the best to the task – LightStar™ Torque Wrench series.

Ensure that your auditing is accurate the first time, every time.

The LightStar™ Torque Wrench technology is designed for auditing quality and is positioned inside an entire ecosystem of quality products to meet all your continuous quality improvement needs.

Unique vibration patterns signal in spec, out of spec, over torque, and torque curve exception (misread)

Upgrade previously purchased wrenches.